PF1315 impact crusher is a high-performance crusher. Its impact frame forces the material into the cavity. The motor drives the rotor to accelerate the crushed materials. This machine has a large crushing cavity and is suitable for secondary and tertiary crushing applications. Has good production efficiency and safety performance. The following is a detailed description of the PF1315 impact crusher:

It is an advanced crusher with excellent performance in crushing soft materials. It uses a modified high manganese steel hammer to refine the grains. It has good toughness and wear resistance. The service life is more than one year, suitable for a variety of processing conditions. PF1315 double-rotor impact crusher has a long service life. It is also suitable for medium and fine sizing applications.

It is a kind of impact crusher, which can crush materials with a diameter between 100mm and 500mm. It has a high compressive strength of 320MP and a large compression ratio. Easy to maintain and save operating costs. Its rotor and blow bar can be easily locked. Its powerful blower has reliable performance and long service life. It is recommended to crush hard materials in medium to large quantities.

It is a powerful, reliable and efficient impact crusher, which can handle various materials. Its secondary crushing method can achieve high-speed, large-capacity crushing, low energy consumption, and low operating and management costs. It is one of the most popular impact crushers of BTMA Machinery. It is characterized by a longer rotor body, a split machine, and a simple design. The slender rotor design of PF1315 and the adjustable gap between the rotor support and the impact frame can change the size of the finished powder.

This impact crusher is manufactured by BTMA. It has a powerful hammer, and its work hardening capacity is twice that of traditional hammers. The high-quality hammer also improves the lubricating ability of the machine. Pf1315 has a high-quality rotor shaft that is easy to adjust. The hammer helps the crusher to operate efficiently and safely. It can reduce the labor intensity of the cement plant.

The impact crusher is a powerful crusher, available in two sizes. The maximum processing capacity of PF1315 is 260 tons per hour. It also has a larger capacity of 660 tons. PF1315 can crush various types of materials, including rock, concrete and asphalt. Its powerful performance makes it an excellent choice for various construction purposes. It can be used for aggregate production and also for the feed of mills.

For more details contact WhatsApp +8618238543716

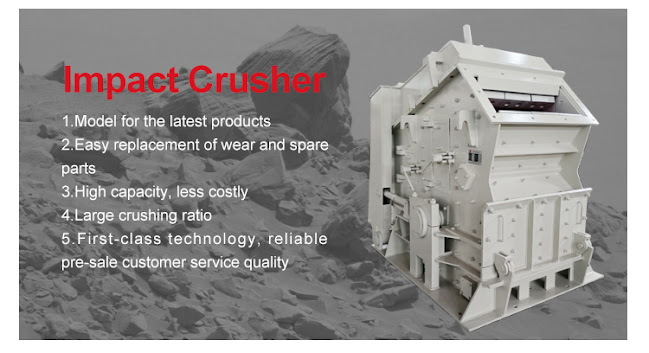

回复删除Impact Crusher